Insights

Kanaflex finds renewed image, focus under new leadership

Blog

23.04.2025

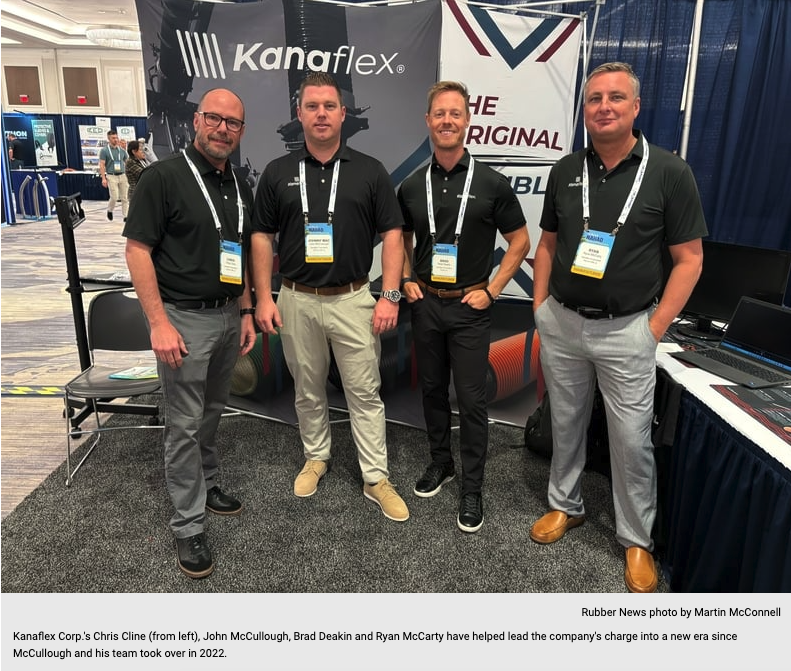

VERNON HILLS, Ill.—Kanaflex Corp. National Sales Manager Chris Cline says that change is in the air in northern Chicagoland.

The company has been on the rise since John McCullough took over as its executive vice president of sales in 2022, Cline said, with no signs of stopping. The company is moving forward with a renewed business focus following advisory meetings with a market researcher, according to McCullough.

The company produces about 12 million feet of hose every year, according to McCullough, ranging from half inch to 12-inch diameter.

Less than an hour outside of downtown Chicago in Vernon Hills, the 75-employee firm has spent the past three years attempting to thread the needle between two seemingly conflicting efforts: carving out a consistent niche in a competitive market, and completely reinventing the company and its image. But McCullough feels that the company is making strides on both accounts.

“It is a huge change,” McCullough said. “In the past, Kanaflex always had good quality products, but it was looked at as somewhat stagnant. Now, under new ownership, we’ve certainly updated and identified the gaps in the business and aligned it with either technology or key people, and we have looked for experts in those fields to be able to fill out and address that gap.”

A company at rest is either going to stay at rest or worse, die off completely, Cline said. But in order to reshape the company without rocking the proverbial boat too much, the Kanaflex team wanted a solid plan in place for its new direction.

“It’s about understanding what you have,” McCullough said, “and creating a plan that has clear directive, and executing that plan.”

Products and processes for the ‘new’ Kanaflex

Going along with Kanaflex’s new direction, McCullough and the firm’s other top brass wanted to keep the company from getting stale. Enter the FlexDUCT-brand and its new polyurethane hose, one of the company’s latest products to hit the market.

“We have a product development process where we work with our existing distributors, we work with end users, we work with OEMs,” McCullough said. “And just from the daily business process, there (are) requests that are curated and they go into the product development funnel. We evaluate those opportunities and look at the need, and the scale of that need.”

Kanaflex and the new FlexDUCT product featured heavily in this year’s annual NAHAD conference in Tampa, Fla. Available now for applications like woodworking, dust collection, and street sweeping, the new product came from a company-wide desire to solve a major hose industry problem: shipping air to customers.

“One of the biggest challenges with hose is that you’re shipping air, and so when we have a pre-paid order going to our customer, that is an opportunity to add on other products,” McCullough said. “We have a ducting line that we wanted to expand on because we see an opportunity to add those products onto existing orders and expand our business with customers. It fits into industries we’re currently servicing right now.”

The FlexDUCT brand is one of eight hose brands in the Kanaflex product catalog, and one of the brands that the firm feels it can get the most mileage out of. Cline and other company officials have pointed out that ducting is popular across multiple market segments in the hose world, making it one of the firm’s most versatile offerings.

“There’s a vast customer base for that product. They’re already buying Kanaflex hoses so we thought it made sense to add a built-up ducting line.”

The hose is made from completely virgin material in order to achieve consistency throughout the manufacturing process, McCullough said. While the company’s all-virgin practices might be sacrificing parts of its sustainability efforts, he believes the positives of using virgin raw material are non-negotiable.

“(Recycled material) does bring other benefits from a sustainability standpoint, but it also creates inconsistencies at the point of manufacturing,” he said. “That’s something that we see consistency as a requirement for a hose. That’s something that because the dimensional standards and tolerances are fairly tight, the raw material being virgin allows us to really deliver a quality product.”

The company’s willingness to use virgin raw materials is a “key differentiator” between Kanaflex and other firms, Cline added. Lining that up with other differentiating factors has allowed Kanaflex to move into what officials believe is a relative position of strength.

Click Bold below to link to original article.

Originally written by Martin McConnell with the Rubber News.